Automotive parts from Coko

16 different, complex automotive parts at an attractive price. To achieve this, an ARBURG turnkey system provides plastics processor Coko with the necessary efficiency and variance in production.

16 different, complex automotive parts at an attractive price. To achieve this, an ARBURG turnkey system provides plastics processor Coko with the necessary efficiency and variance in production.

Two robotic systems handle 16 different components with up to 15 metal inserts each.

The application meets the automotive customer's 10 ppm requirement for premium quality.

Thanks to full automation, complex parts can be produced at an attractive price.

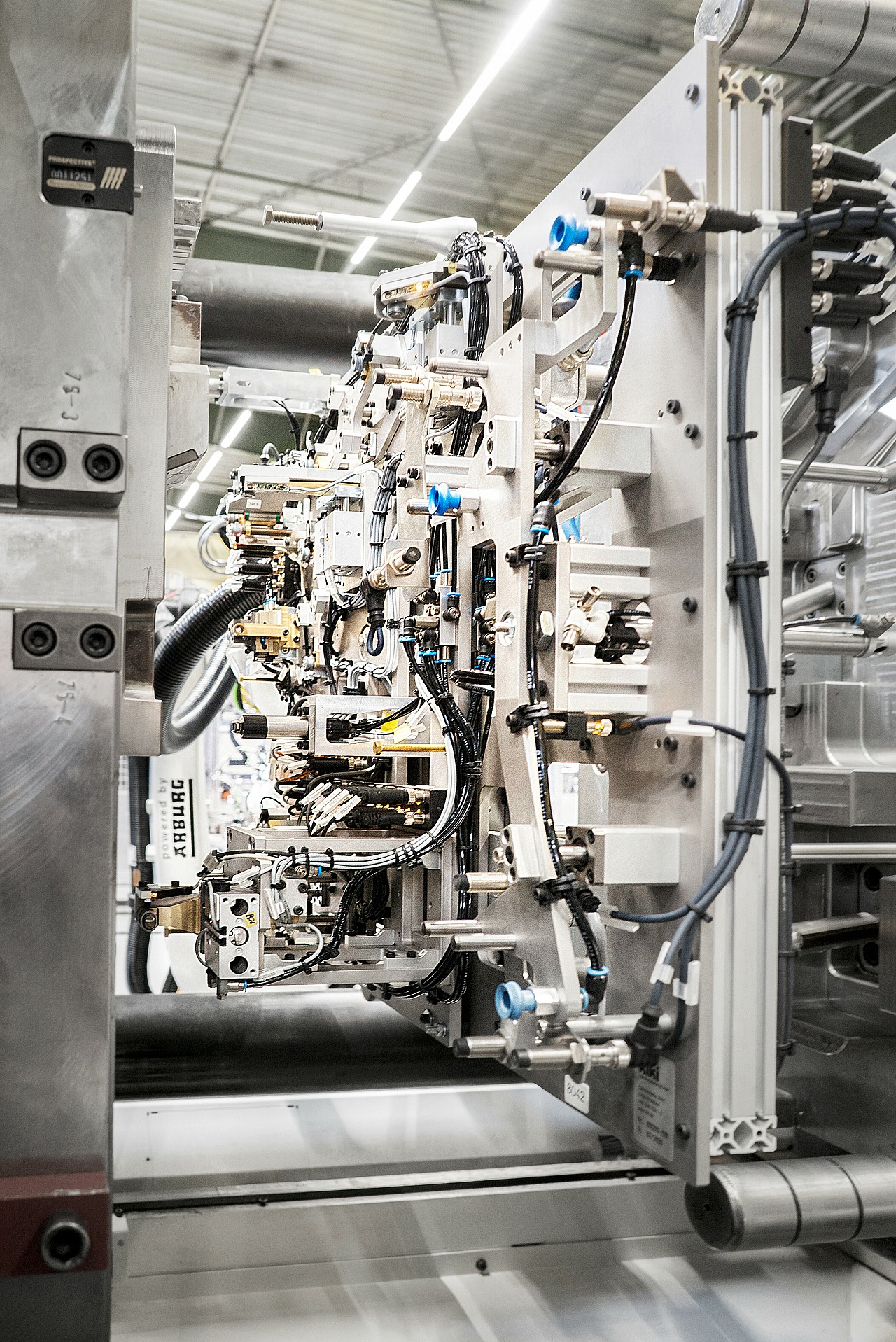

A turnkey system based around a hydraulic ALLROUNDER 920 S with a clamping force of 5,000 kN is used. Four functional and structural components made of glass-fibre reinforced PA6 are overmoulded with up to 15 metal inserts in the mould. For this, up to five different inserters are separated simultaneously in the feed station. A KUKA robot places these in a loading platen. From there, a second robot picks up the inserts and, after removing the finished component, positions them simultaneously in both mould halves. After the injection moulding process, a check is made to ensure that all metal inserts are properly positioned in the component. Another twelve visible part variants without inserts are injection-moulded from PP (filled with 20% talcum), removed by the robot and subsequently transported to a clip assembly station, where they are fitted with up to eight clips in the "free-flying" gripper under the assembly head.

Variance, automation and the precision of the turnkey system offer a wealth of possibilities in the automotive segment. The result is high-quality interior components that meet the most stringent quality requirements yet can be manufactured cost-effectively and without finishing work.

“The high level of automation is critical in enabling us to offer the complex parts at an attractive price and to meet the highest quality requirements. ”

Sascha Böning, Industrial Engineering at Coko