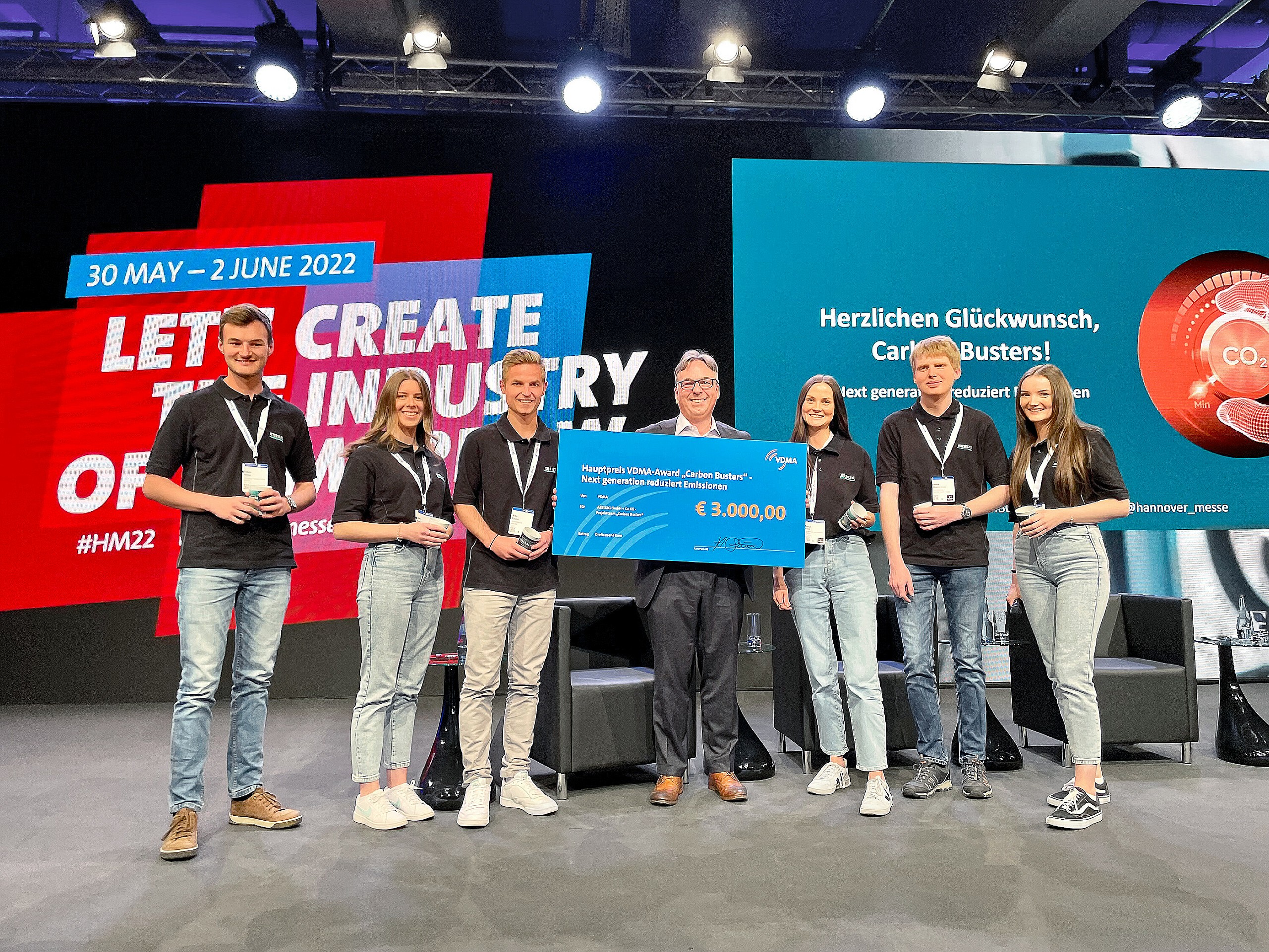

Award-winning: Environmentally friendly concept

The main criteria for the jury's decision were clearly formulated goals, a comprehensive elaboration of the project, and the drive through to implementation. "We are delighted that our concept for environmentally friendly coffee consumption was so well received by the VDMA and, above all, by ARBURG", said Tobias Helber, a first-year IT specialist, thanking the project team. Tobias and fellow trainees Denise Bohnet, Svenja Bross, Sonja Fritz, Mika Hauser, and Jannik Münstermann had invested around 250 hours in the concept and have since already realised some ideas at ARBURG's central location in Lossburg.