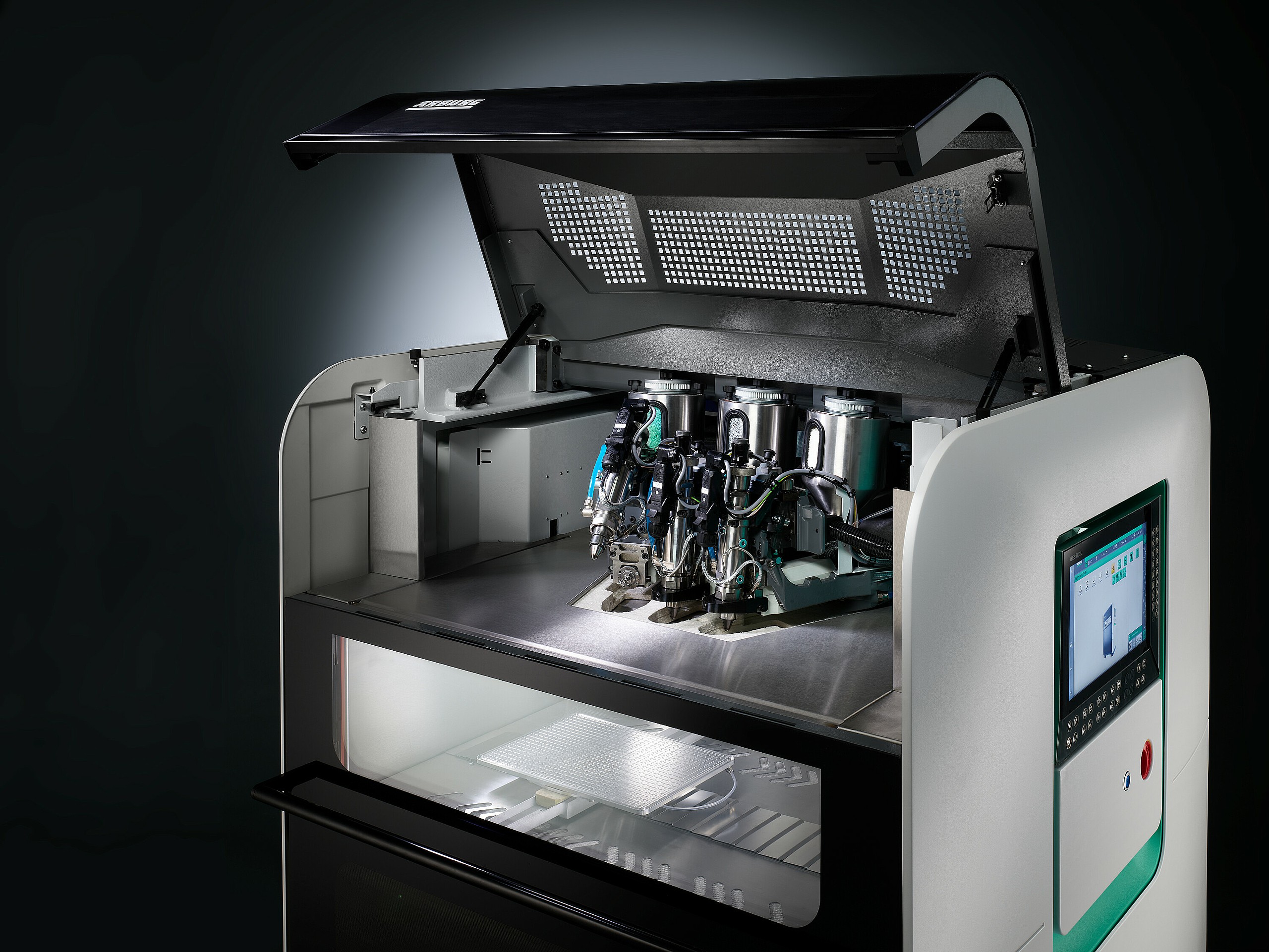

Additive manufacturing of complex functional parts

The designation 750 stands for the available part carrier surface area in square centimetres. Compared to the freeformer 300-3X, it offers 2.5 times more space for parts with dimensions of up to 330 x 230 x 230 millimeters. "3X" stands for the three axes of the part carrier that can be moved in the x, y and z directions.