Additive manufacturing

Customised 3D printing – the ARBURGadditive Group offers freeformers from ARBURG and 3D printers from innovatiQ. Plus the ARBURG Plastic Freeforming (APF), Fused Filament Fabrication (FFF) and Liquid Additive Manufacturing (LAM) technologies.

This might also be of interest

From practical experience – for practical use. That's how we share knowledge. You benefit from our expertise. Targeted, fast, and cooperative. With our machines, for your purposes.

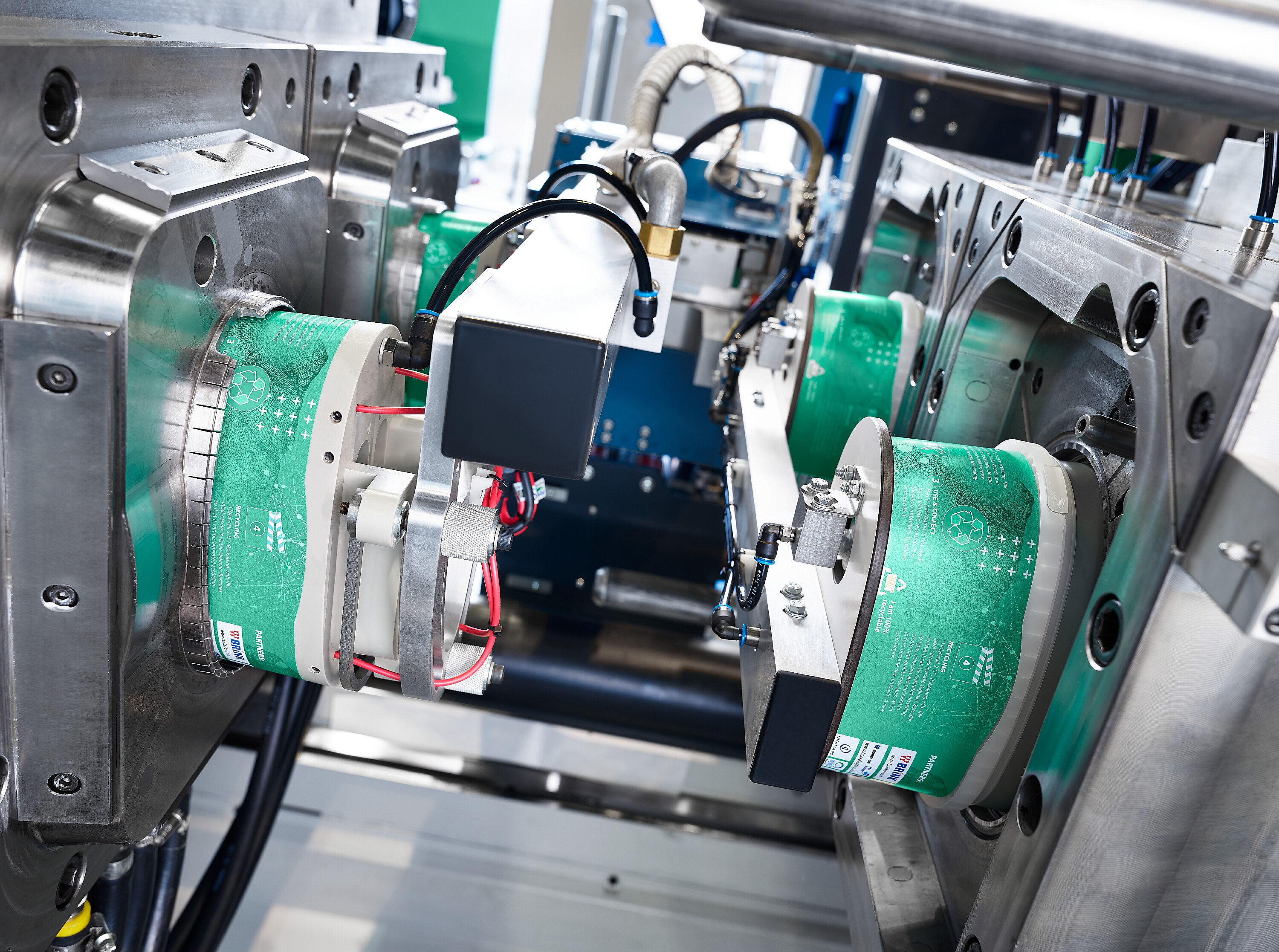

Electronics, medicine, mobility, packaging, complex components for a wide range of areas. This is where you excel. So do our machines and solutions.

Take advantage of our expertise – from moulded part design to mould and machine configuration. And application technology, for example in our Customer Center.